It had to sincronyse with the computer USB port in order to run the code.

The issue about Linux and Windows was that this USBtinyISP has no cristal neither resonator. Through the Linux notebook I was able to programm the board and succed in using it later (mostly with the display setup tests). Our tutor Kenzo provided us with a Linux notebook and it was very handy. The second was about the software to program the board as a programmer. I had to cut the edge of the board - USB connection / short cut to computer pads - to make it really connect to a computer. When programming the board I faced two major problems. Tomorrow I will have another chance to re-sold components and test my PCB board again. Later, I found out there was one resistor I miss read (two units) and, because of that, the success and happiness of pluging it on and seing the leds bright just vanished. It was a situation I had to adapt.Īfter having the plate done, I did the picking for eletronic components. The result was nice, but my local tutor already said I may expect some complains about this tool change. The tool we had in the lab was a vcut 20° with and edge of 0,1 mm. The first solding attempt faild and I had at that point only one PCB board cut.

ShopBot was the machine and VCarv the gcode generator. My last opportunity to operate a milling machine was january 2017 when we add furniture to our Fab Lab (with an OpenDesk website project). Fab Modules was new in it and I really liked. It has been a while since I first start operating milling machines. Preparing the plate with a milling machine was easier. I kept the impression to sold is about controling the way you breath. The board documentation is very good! And gives more information about it.Īt this moment I still don't have much experience with solding components, but I had some experience in the past. Brian is the author and the link to his project page is here. This week assignment was based on a project. Mill - endmill - 2,00 mm cut diameter - 02 flutes - example here.

Mill - engraver - 20°edge - example here.

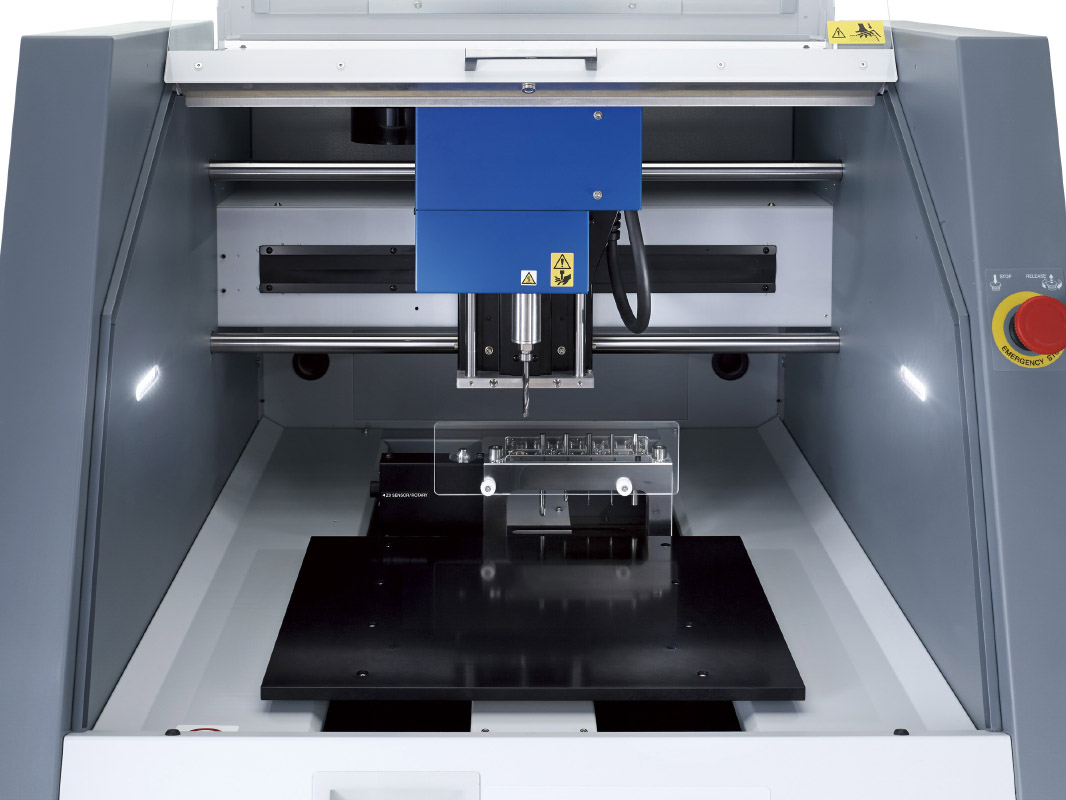

Phenolic paper - copper layer for circuit boards - standard 1,7 mm thickness - example here. The manufacture link to its own documentation and information will be found here. One may also check this tutorial explaining how to mill a coin (and how to operate and setup the working material in a machine like Roland MDX-40A). Roland MDX-40A - Machine's tutorial, please click here. Make an in-circuit programmer by milling the PCB (program it, so that you can use it to program your board in Electronics Design week, and in other weeks)Ĭlass material: Electronics Production Equipment listed below: Eletronics - assembling PCB plate with very small things.

0 kommentar(er)

0 kommentar(er)